Alliance Precision Plastics

Alliance Precision Plastics

Rochester, NY

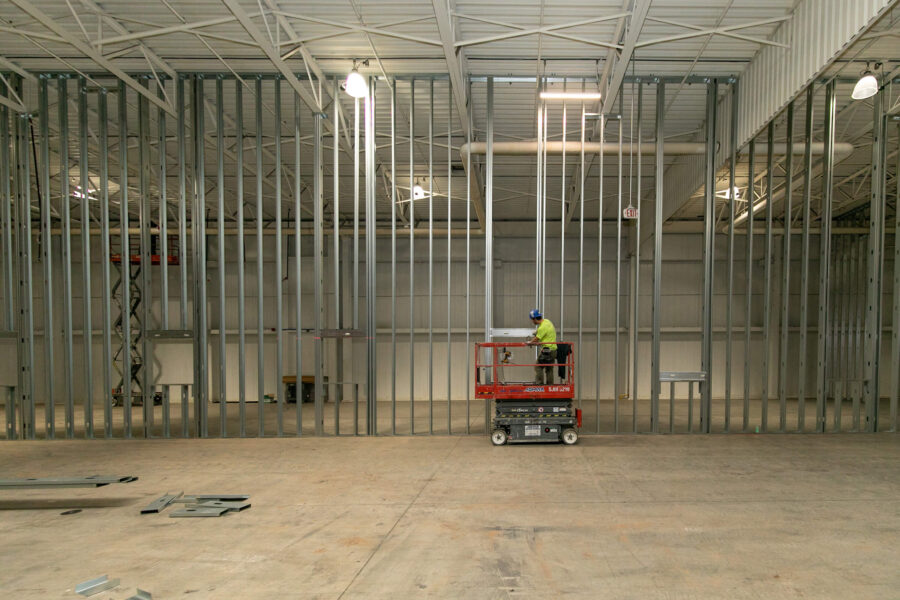

Conductor partnered with their existing tenant Alliance Precision Plastics to design-build +/- 96,000 SF of adjoining vacant warehouse space to build-to-suit a new blow-molding production facility. Fit-out also included 15,000 SF of employee support areas including office and conference space, laboratory, break areas, and new restrooms. A custom clean room was also included in the production area build-out.

Scope Highlights

The Architect and Engineer of Record for the project was Stantec.

As part of the developer contribution to the project a new 3,500A power room was constructed to support the production requirements of the tenant, along with the addition of 6 new cooling RTU’s for the production environmental controls.

Conductor worked closely with the tenant and Concord Electric to design build the power distribution on the production side of the facility, including the design and construction of a custom rack system to support the conduit distribution to the equipment rows.

Civil improvements included the connection of new upgraded sanitary and electrical utilities to the tenant space, along with a series of tank and equipment pads for setting of tenant provided production and mechanical equipment.

Conductor worked closely with the tenant’s equipment providers and staff to support and install all necessary mechanical and utility connections.